Electrorefining

RSR Anodes are designed to make the hydrometallurgical process as efficient and profitable as possible by:

- maximizing extraction process quality

- minimizing maintenance needs

- optimizing energy utilization

- Increased electrical conductivity

- Low oxygen overpotential

- Rapid formation of uniform, adherent MnO2 and PbO2layers

- Resistance against anode passivation

- Enhanced mechanical integrity

- No short circuits related to dimensional instabilities

- Resistance to penetrating corrosion

With over 50 years of lead metallurgy experience and state-of-the-art casting and rolling mill equipment, RSR Anodes are produced to customer specifications for either new facilities or to replace spent anodes.

Cold rolling after casting further enhances the productivity and life span of our anodes for extracting copper, zinc, cobalt and nickel. Rolling breaks up the grain structure, then elongates and orients the grains which become more homogenous in size.

This not only improves the conductivity but it also:

- Further reduces porosity

- Promotes even conditioning and corrosion resistance

- Safeguards against creep

Cast anodes are also manufactured for specific applications at customer request.

SURFACE CONDITIONING

Management of the oxide layer (PbO2) is the key to enhanced anode performance in a harsh working environment. As with other aspects of anode manufacture, we have developed a surface finish for optimum electrochemical performance. The alloy plays a role as does the surface roughening. Our environmentally safe surface pre-treatment for zinc anodes rapidly produces a thin, adherent film of PbO2 on the rough, irregular surface with a deep, micro-texture featuring indentations of up to 1mm.

The MnO2 forms over the protective film of PbO2. Surface treatment of Zinc anodes is also critical in minimizing initial mud formation.

The continuous build-up of oxidation products causes short-circuits, decreases conductivity, and compromises the structural integrity of the anodes if the corrosion process penetrates into the anodes. RSR Anodes are less prone to such issues and engineered for optimal performance.

COPPER HANGER BAR

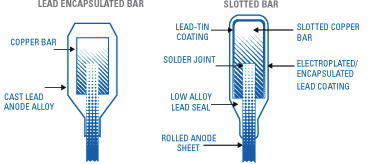

RSR’s copper hanger bar is another unique feature that makes our anodes more productive and extends their service life. The rolled alloy sheet is fitted into a slot milled into the copper bus bar and attached by a soldering method that ensures a complete bond. There is almost no differentiation in current between the copper and alloy sheet. This consistency continues for the life of the anode.The bar and joint are protected from electrolyte mist and accidental submersion by either encapsulating or electroplating with a lead alloy coating.